| Sign In | Join Free | My adobecards.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My adobecards.com |

|

Brand Name : OHMALLOY

Model Number : Inconel601

Certification : ISO ROHS

Place of Origin : China(Shanghai)

MOQ : 50kg

Price : negotiable

Payment Terms : , L/C, T/T

Supply Ability : 20000T/Year

Delivery Time : 7-20days after your deposit received

Packaging Details : IN Wooden box

Standard : ASTM B166

Surface : Bright&Block

OD : 0.2~80mm

Wall : 0.01~10mm

Length : 0.2~6000mm

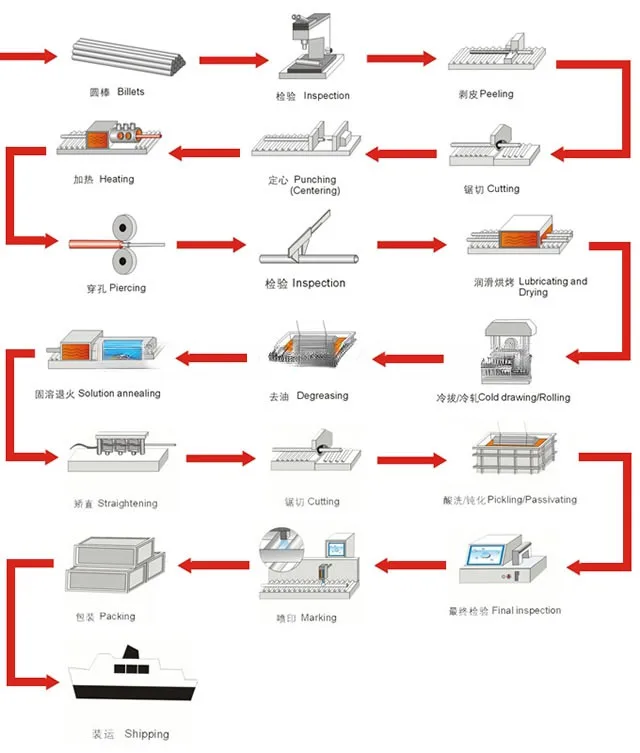

Craft : Cold Drawing

Shape : Tube

Common Name : FeNi52

Application : Glass sealing

Ni% : 51.5~52.5

Cold Drawing UNS N14052 Alloy52 Tube / Pipe 15x 1.2mm for glass sealing produced by ASTM F30

Chemical Composition

| Grade | C% | P% | S% | Mn% | Si% | Cu% | Cr% | Mo% | Ni% | Co% | Fe% |

| Alloy52 | Max 0.05 | Max 0.020 | Max 0.020 | Max 0.80 | Max 0.30 | / | / | / | 51.5~52.5 | / | Bal. |

Specifications

| Grade | Common Name | Common Name |

| Alloy | Vacodil520 | NILO 52 |

Physical Properties

| Grade | Density | Resistivity |

| Kovar | 8.25 g/cm3 | 0.43 |

Grain size of Alloy52

The grain size of the alloy deep-drawing belt should not be less than level 7, and the grain size less than level 7 should not exceed 10% of the area. When the average grain size of the strip with a thickness of less than 0.13mm is estimated, the number of grains along the thickness of the strip should be no less than 8.

Welding performance of Alloy52

The combined gold has good welding performance and can be brazed and spot welded. The combination of gold and soft glass should be pre-oxidized before sealing.

Coefficient of Expansion

| Alloy | Linear Coefficient of Thermal Expansion a,10-6/°C | |||||||

| 20-200°C | 20-300°C | 20-350°C | 20-450°C | 20-500°C | 20-600°C | 20-700°C | 20-800°C | |

| Kovar | 10.4 | 10.2 | 10.3 | 10.3 | 10.3 | 10.8 | / | / |

Heat Treatment For Alloy52

(1) Stress relief annealing In order to eliminate the residual stress of parts after machining, stress relief annealing is required: 430~540℃, heat preservation 1~2h, furnace cooling or air cooling. [1]

(2) Intermediate annealing In order to eliminate the work hardening phenomenon caused by the alloy in the process of cold rolling, cold drawing and cold stamping, in order to facilitate the continued processing. The workpiece needs to be heated to 700~800℃ in a vacuum or protective atmosphere for 30~60min, then furnace cooled, air cooled or water quenched.

(3) Pre-oxidation treatment When the combined gold is used as a sealing material, it should be pre-oxidized before sealing. A uniform and dense oxide film is formed on the surface of the alloy. The parts are heated in saturated wet hydrogen at 1100°C for 30 minutes, and then oxidized in the air at about 800°C for 5-10 minutes. The weight gain of the parts should be 0.1~0.3mg/cm2

|

|

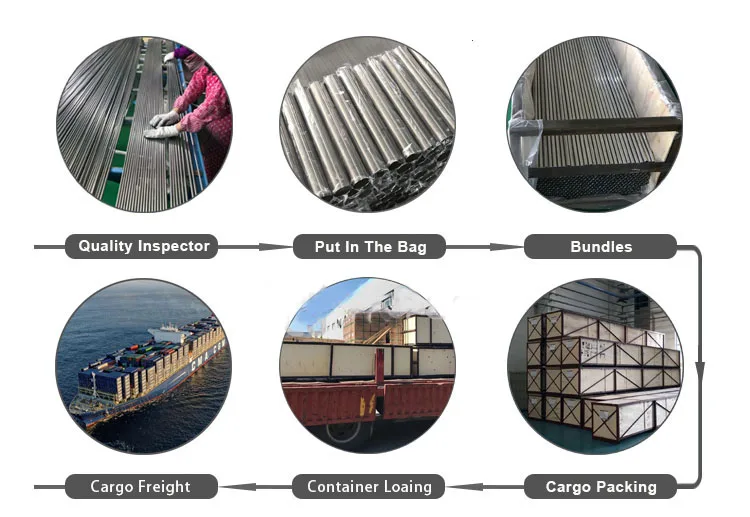

Cold Drawing UNS N14052 15x1.2mm High Temp Alloys Images |